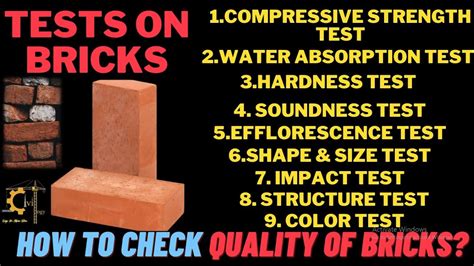

hardness test of brick|how to measure brick quality : store Hardness Test on Brick. Soundness Test on Brick. Impact Test on Brick. Shape and size Test on Brick. Structure Test on Brick. All types of tests on brick full detail and specification are as follows. 1. Laboratory Tests on Brick.

16 de ago. de 2022 · Links de trans - Grupos de Telegram e Whatsapp Brasil. 16 de agosto de 2022 Por. Toda a gente quer saber tudo sobre links de trans, mas pouca .

{plog:ftitle_list}

webLance: R$ 89.600,00 - CHEVROLET/S10 LT DD4A CABINE DUPLA - Ano: 2022 - VERMELHA - Diesel. Aproveite. Envie seu lance! - Leilomaster

Hardness Test on Bricks. A good brick should resist scratches against sharp things. So, for this test a sharp tool or finger nail is used to make scratch on .

Learn how to check brick quality with six easy steps, including visual inspection and simple tests like tap, drop, crack, and water absorption tests.

Hardness Test on Brick. The hardness test of bricks is used to determine the resistance of bricks to abrasion. In the hardness test of the bricks or scratches made on the .

Crushing Strength Test, Water Absorption Test, Presence of Soluble salts or Efflorescence Test, Hardness Test, Shape and Size Test, Soundness.Step in Compressive Strength of brick test procedure. Take 5 nos of bricks randomly. Put it into the water for 24 hours at normal room temperature. Take it out from the water after 24 hours and remove the water contents naturally . Hardness Test on Brick. Soundness Test on Brick. Impact Test on Brick. Shape and size Test on Brick. Structure Test on Brick. All types of tests on brick full detail and specification are as follows. 1. Laboratory Tests on Brick. Hardness. In this test, a scratch is made on brick surface with the help of a finger nail. If no impression is left on the surface, brick is treated as to be sufficiently hard. 6. Soundness. Two bricks are taken, one in each hand, .

Hardness of brick is tested by the compressive testing machine or UTM machine. In this test, the brick is placed inside the testing machine and a compressive load is applied on the brick until the brick breaks. The reading .Three basic types of brick are un-fired, fired, and chemically set bricks. Each type is manufactured differently. . Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness .

Hardness test on bricks. The hardness test on bricks is a field verification test. Hence they are performed on-site. A good brick should resist scratches against sharp things.3.2 All apparatus and testing equipment shall be calibrated at frequent intervals. 3.3 The number of specimens for the test shall be selected according to IS 5454 : 1976. 4 METHODS 4.1 For Solid Bricks 4.1.1 Apparatus A compression testing machine, the compression plate of which shall have a ball seating in the Here’s where brick testing steps in, providing valuable insights into a brick’s suitability for your specific needs. . Tests like the hardness test ensure the bricks have the necessary characteristics to perform their intended function. Aesthetics: Bricks play a significant role in a building’s visual appeal. The color test helps .

Hardness test. Use a sharp nail or make scratch marks on the bricks. A good brick is resistant to any scratches and marks on its surface. If the brick does not hold any scratch marks, then it is called as a hard brick. Structure test. This is perhaps the simplest of tests to check the quality of bricks. Pick any brick from the cluster and break .3. Hardness test. The ideal brick must be able to resist any scratches induced by sharp objects. So, for this specific test, a sharp tool or fingernail is used to create scratches on bricks. If there are no impressions of any scratches, then the brick is considered to be a hard brick. If brick surface area is covered with salt deposits between 10-50 % then it has moderate efflorescence. If brick surface area is covered with salt deposits less than 10% then it has slight efflorescence. Efflorescence Test Brick Dimension Test. Select twenty bricks randomly from construction site.Standard Methods of Sampling and Testing Brick and Structural Clay Tile [Ref. 1] or CSA A82 [Ref. 3]. The minimum compressive strength, maximum water absorption and maximum saturation coefficient are used in combination to predict the durability of the bricks in use. The saturation coefficient, also referred to as the

compression tester adapter with schrader valve

Hardness of Brick In materials science, hardness is the ability to withstand surface indentation ( localized plastic deformation ) and scratching . Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing.What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a mineral is defined as its "resistance to being scratched". A list of the Mohs Hardness Scale Minerals is shown in the table below.

(3) Hardness test on bricks: In this test, a scratch is made on brick surface with the help of a finger nail. If no impression is left on the surface, the brick is r sufficiently hard. (4) Presence of soluble salts: The soluble salts, if present in cause efflorescence in brick work. For finding out the presence of soluble salts in a brick, it .

Mohs hardness, rough measure of the resistance of a smooth surface to scratching or abrasion, expressed in terms of a scale devised (1812) by the German mineralogist Friedrich Mohs. The Mohs hardness of a mineral is determined by observing whether its surface is scratched by a substance of known or . For this reason the Mohs test, while .

compression tester adapters 10mm

In absorption test on brick, how many hours it has to be soaked in cold water? a) 19 hours b) 5 hours c) 6 hours d) 24 hours View Answer. Answer: d . Using hardness apparatus c) Using hammer d) Using chisel View Answer. Answer: .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find . A good brick should absorb less than 20% of water when it is immersed in water for 24hrs. If the brick absorbs more than the allowable limit. It absorbs water from cement mortar during its bonding. This eventually affects the brick bonding strength. Water absorption test on brick:-To test the water absorption follow the below procedure: Steps for Performing the Mohs Hardness Test . Find a clean surface on the specimen to be tested. Try to scratch this surface with the point of an object of known hardness, by pressing it firmly into and across your test specimen.For example, you could try to scratch the surface with the point on a crystal of quartz (hardness of 9), the tip of a steel file (hardness .

Hardness testing standards have been set by various organisations such as The American Society for Testing and Materials (ASTM) and The International Organisation for Standardisation (ISO), prescribing specific varieties of a hardness test determined by factors such as the type of indenter, applied force, and procedure of force application. Perform the Mohs Hardness Test. The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: your fingernails (2.5) a copper coin or piece of chalk (3.5) a pocket knife or piece of glass (4.5-5.5) a quartz point or unglaze porcelain (7.0) a hardened drill bit (8.5) Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness Testing. Hardness testing is important for a number of different reasons. The hardness of a material can be a critical parameter in its . This image contains a table relating mineral hardness for a few selected minerals with common objects that could be used to test hardness. The title, Mohs Hardness Scale is accompanied with the National Park Service arrowhead symbol. The minerals are listed from hardest to softest with their hardness scale number as follows: Diamond, 10 .

tests on bricks for construction

Brinell Hardness Test; Rockwell Hardness Test; Vickers Hardness Test; Knoop Hardness Test; Mohs Hardness Test; 1. Brinell Hardness Test. The Brinell hardness test measures the hardness of the material in terms of the indentation caused by a constantly applied concentrated force. The force is applied using an indenter on the specimen. The compressive strength test on brick specimens was performed following the guidelines of (ASTM C67 Citation 2020). All tested brick specimens were subjected to a compressive load at the rate of 1.25 mm/min. The flexural strength of brick specimens was determined following (ASTM C67 Citation 2020) at a 1.27 mm/min loading rate. The details are .

A method of testing for hardness is to hold the brick in one hand and give it a light tap with a hammer. The sound caused by the blow should be a dull ringing tone and not a dull thud. Obviously different types of brick will, when tapped, give off different sorts of sound and a brick that gives off a dull sound when struck may possibly be hard . Dimension test of bricks, Test on Bricks, Testing Of Bricks: Dimension Test (IS: 1077), Tests which are to be conducted on bricks for selecting it as a building material, Determination of dimension of brick, dimension test of brick (brick size), 20 pieces out of selected pieces (Table) are taken and are laid flat as shown in Fig. What is the dimension of .

how to test brick quality

compression tester adapters oreillys

Gostaríamos de exibir a descriçãoaqui, mas o site que você .

hardness test of brick|how to measure brick quality